How we

work

“Quality is to meet the needs of the customer and exceed their own expectations while continuing to improve.“

William Edwards Deming

HOW WE

WORK

QUALITY IS TO MEET THE NEEDS OF THE CUSTOMER AND EXCEED THEIR OWN EXPECTATIONS WHILE CONTINUING TO IMPROVE.

William Edwards Deming

Know-how of Car Plast Extrusion: knowledge and expertise

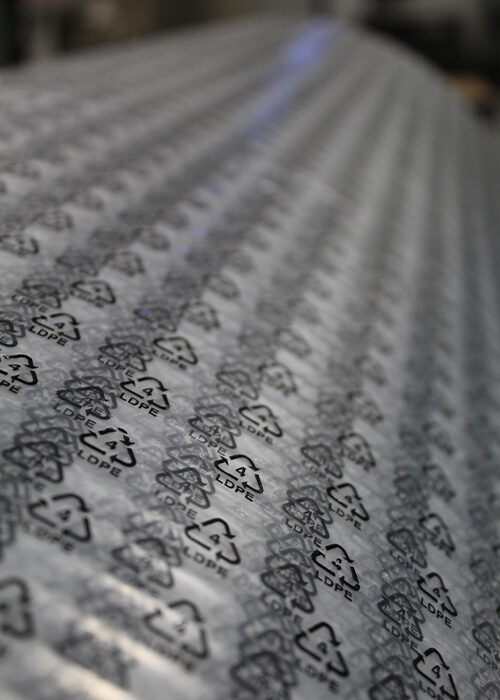

Knowledge of the technical characteristics of polymers and attention to the selection of raw materials: these are the fundamental aspects on which we at Car Plast Extrusion base our activity, our “know-how”.

Knowing the materials we have available, understanding their properties, limits, potential, how to transform them, and which tools to use, has allowed us to build a unique experience: thanks to this, we are able to develop specific formulations to achieve the best possible result from our products.

The diversified and wide availability of raw materials allows us to have a constantly replenished warehouse, thus ensuring production continuity in the face of any market shortages.

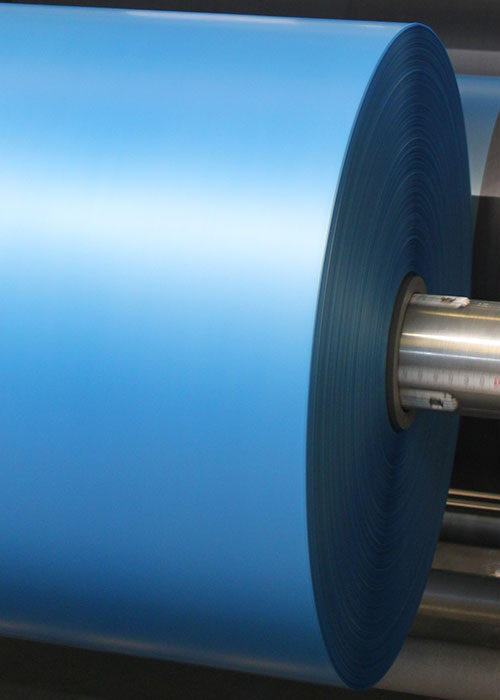

Raw materials, knowledge, and expertise fuel a production department with state-of-the-art production lines, enabling us to achieve a distinctive level of quality in the industry.

High Production Coordination

Our team is focused on a common goal: to produce a product that is technically and qualitatively in compliance with the highest quality requirements defined by the company.

A first step towards continuous improvement of our business processes was taken with the achievement of ISO 9001:2015 Certification of our Quality Management System. This implementation has allowed us to coordinate the various business functions, establish control procedures, and trace a growth path to achieve the objectives set by our policy and the satisfaction of our customers.

Organization is the guiding behavior that drives us both in the production process and in the company structure, with defined roles, competencies, and responsibilities. Car Plast Extrusion believes in employee engagement and therefore promotes an inclusive culture in which everyone can feel empowered, sharing objectives, successes, and failures.

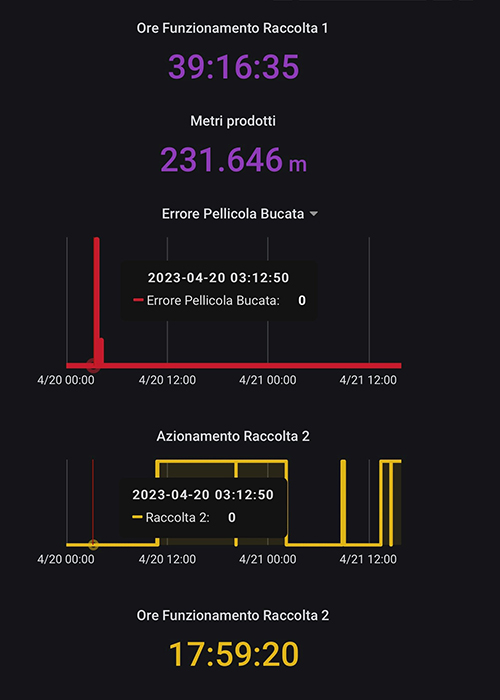

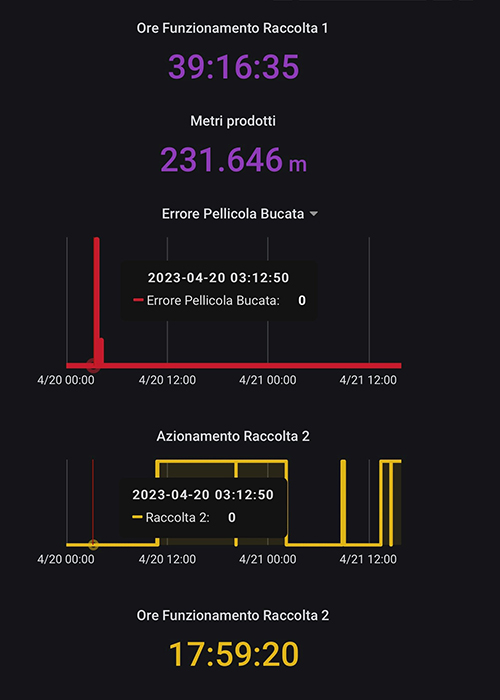

Constant Process Control

In addition to product verification activities during the processing stages, process monitoring is carried out through a customized MES production management and control system, which detects real-time data from the production lines for each batch in production, providing a series of essential information:

- production progress status;

- production times and volumes;

- equipment performance;

- raw materials used;

- energy consumption

These functions are complemented by maintenance management and control, including planning, alerting for any critical limits, consultation of elaborations, and customized benchmark analysis.

Attention to Safety

For us at Car Plast Extrusion, quality is synonymous with safety and guarantee, and to ensure them, several interventions have been implemented for some time, such as:

- storage of raw materials and pallets in enclosed spaces to reduce the risk of contamination;

- separation of raw materials from finished products in separate warehouses;

- registration and tracking of raw materials and products used for complete traceability of each production batch;

- plant areas with closed and controlled access;

- production areas with continuous air purification system

Know-how of Car Plast Extrusion: knowledge and expertise

Knowledge of the technical characteristics of polymers and attention to the selection of raw materials: these are the fundamental aspects on which we at Car Plast Extrusion base our activity, our “know-how”.

Knowing the materials we have available, understanding their properties, limits, potential, how to transform them, and which tools to use, has allowed us to build a unique experience: thanks to this, we are able to develop specific formulations to achieve the best possible result from our products.

The diversified and wide availability of raw materials allows us to have a constantly replenished warehouse, thus ensuring production continuity in the face of any market shortages.

Raw materials, knowledge, and expertise fuel a production department with state-of-the-art production lines, enabling us to achieve a distinctive level of quality in the industry.

High Production Coordination

Our team is focused on a common goal: to produce a product that is technically and qualitatively in compliance with the highest quality requirements defined by the company.

A first step towards continuous improvement of our business processes was taken with the achievement of ISO 9001:2015 Certification of our Quality Management System. This implementation has allowed us to coordinate the various business functions, establish control procedures, and trace a growth path to achieve the objectives set by our policy and the satisfaction of our customers.

Organization is the guiding behavior that drives us both in the production process and in the company structure, with defined roles, competencies, and responsibilities. Car Plast Extrusion believes in employee engagement and therefore promotes an inclusive culture in which everyone can feel empowered, sharing objectives, successes, and failures.

Constant Process Control

In addition to product verification activities during the processing stages, process monitoring is carried out through a customized MES production management and control system, which detects real-time data from the production lines for each batch in production, providing a series of essential information:

- production progress status;

- production times and volumes;

- equipment performance;

- raw materials used;

- energy consumption

These functions are complemented by maintenance management and control, including planning, alerting for any critical limits, consultation of elaborations, and customized benchmark analysis.

Attention to Safety

For us at Car Plast Extrusion, quality is synonymous with safety and guarantee, and to ensure them, several interventions have been implemented for some time, such as:

- storage of raw materials and pallets in enclosed spaces to reduce the risk of contamination;

- separation of raw materials from finished products in separate warehouses;

- registration and tracking of raw materials and products used for complete traceability of each production batch;

- plant areas with closed and controlled access;

- production areas with continuous air purification system

Logistics: from order to delivery

Qualified personnel dedicated to the logistics service carefully oversee all phases of the process: from order reception and customer assistance to verification of all required packaging specifications, from tracking within the production cycle to organization of shipment.

Car Plast Extrusion guarantees maximum quality even in the delivery service: thanks to our transport vehicles and the long-term collaboration with external carriers, the company’s products are delivered quickly both in Italy and abroad. In addition, the extensive warehouses available to Car Plast Extrusion allow for optimal management of all phases, from storage to retrieval of incoming or outgoing goods.