Company

CAR PLAST EXTRUSION IS COMPETENCE: NOT JUST KNOWLEDGE AND KNOW-HOW; PEOPLE: THE REAL KEY TO OUR SUCCESS; EXTRUSION: THE CORE OF OUR BUSINESS

Our company

PROFESSIONALS IN POLYETHYLENE SOLUTIONS

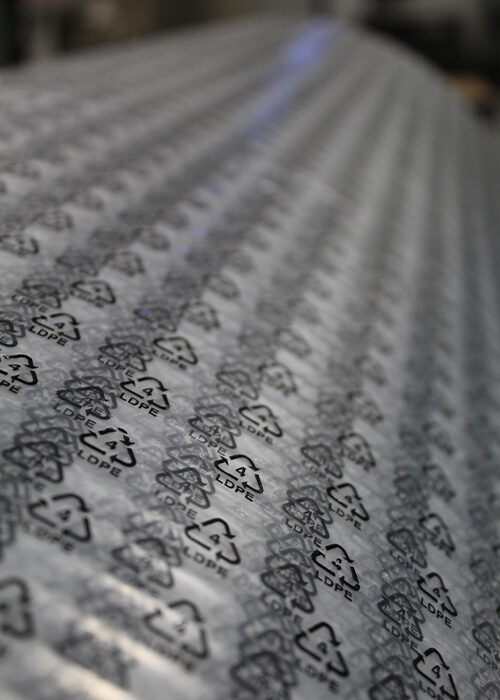

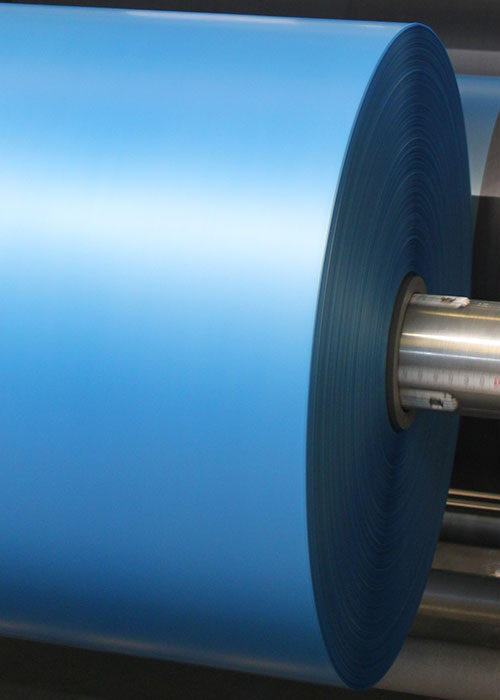

Car Plast Extrusion, with over 40 years of experience in the flexible packaging industry, produces high and low-density polyethylene films. The company, in addition to being recognized for the professionalism of its services, distinguishes itself for the quality of its products; their use ranges in different sectors, from food to industrial.

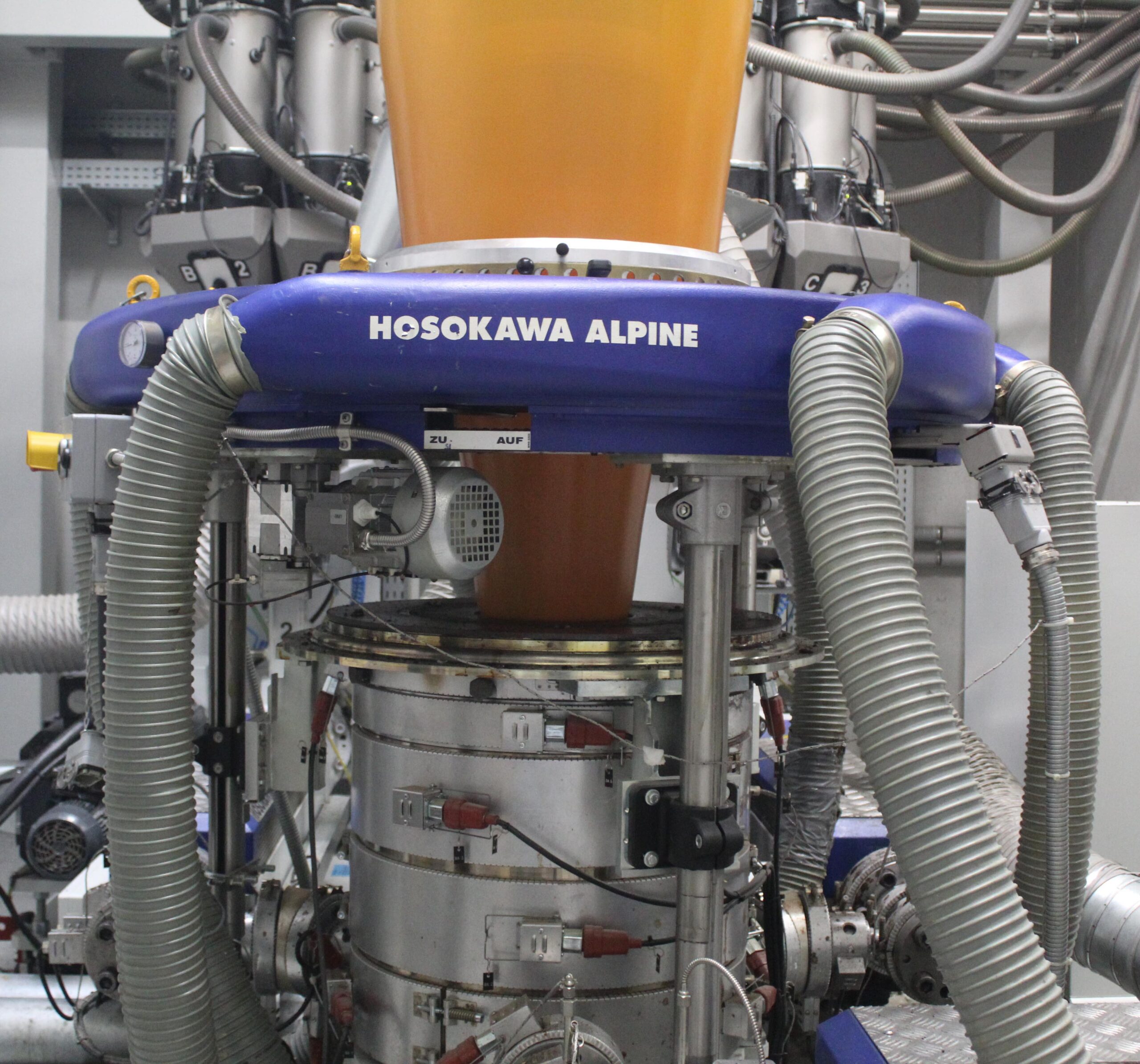

Car Plast Extrusion has always focused its efforts and investments on creating a know-how that allows it to optimize the properties of different polymers through its state-of-the-art equipment, in order to offer solutions that best meet the needs of each customer. At the same time, our production is the result of careful work by a motivated team, always ready to carry out their role with passion and commitment.

COMPANY

CAR PLAST EXTRUSION IS COMPETENCE: NOT JUST KNOWLEDGE AND KNOW-HOW; PEOPLE: THE REAL KEY TO OUR SUCCESS; EXTRUSION: THE CORE OF OUR BUSINESS

Our company

PROFESSIONALS IN POLYETHYLENE SOLUTIONS

Car Plast Extrusion, with over 40 years of experience in the flexible packaging industry, produces high and low-density polyethylene films. The company, in addition to being recognized for the professionalism of its services, distinguishes itself for the quality of its products; their use ranges in different sectors, from food to industrial.

Car Plast Extrusion has always focused its efforts and investments on creating a know-how that allows it to optimize the properties of different polymers through its state-of-the-art equipment, in order to offer solutions that best meet the needs of each customer. At the same time, our production is the result of careful work by a motivated team, always ready to carry out their role with passion and commitment.

Da sempre, Car Plast Extrusion ha focalizzato i propri sforzi e investimenti sulla creazione di un know-how che le permettesse di ottimizzare le proprietà dei diversi polimeri, allo scopo di offrire soluzioni che soddisfino al meglio le esigenze di ciascun cliente. Allo stesso tempo, la produzione dell’azienda si presenta come il risultato di un attento operato da parte di un gruppo di lavoro motivato, sempre pronto a svolgere il proprio ruolo con passione e impegno.

Our history

PRODUCERS OF PLASTIC FILMS SINCE 1975

Car Plast Extrusion, originally known as Car Plast, was established in Bassano del Grappa as a producer of fiberglass coatings.

Seizing the opportunities offered by the flexible polyethylene packaging market, in the late 1970s the company decided to shift its production towards the blown film extrusion of high and low-density films: this marked the beginning of an important growth phase that led to the change in the company’s name to Car Plast Extrusion in 1985.

Thanks to the commitment, expertise and determination of the second generation, the company established itself in the market by proposing products that stood out from the competition for the attention paid to its primary production phase: extrusion.

In the following years, the implementation of new production lines and new products favored constant production growth and an increasingly strong position in the market. These changes laid the foundation for the relocation to the new headquarters in Tezze sul Brenta in 2004.

Starting from 2016, Car Plast Extrusion further increased its technological, structural and personnel training investments, allowing it to distinguish itself even more from its competitors and to become a reference point for flexible polyethylene packaging.

In the following years, the implementation of new production lines and new products favored constant production growth and an increasingly strong position in the market. These changes laid the foundation for the relocation to the new headquarters in Tezze sul Brenta in 2004.

Starting from 2016, Car Plast Extrusion further increased its technological, structural and personnel training investments, allowing it to distinguish itself even more from its competitors and to become a reference point for flexible polyethylene packaging.

Our Values

RELIABILITY

Transparency, respect, and fairness are the values on which we base our work with all stakeholders. Working together with Car Plast Extrusion means dealing with a team of plastic experts who operate with commitment, honesty, and coherence to offer products and services that satisfy the continuously evolving needs of the packaging industry.

We believe that only through dedication, curiosity, and passion is it possible to achieve constant and sustainable development, greater corporate well-being, and significant personal growth.

QUALITY

For Car Plast Extrusion, quality means both creating products that reflect the characteristics and expectations of each customer and carrying out production processes that ensure the achievement of the best results. The concept of quality is also based on a defined policy, in which customer satisfaction is the top priority.

To guarantee it, a Quality Management System has been implemented, consolidated with the ISO 9001:2015 Certification. For us, quality means not only conformity with technical specifications but also the flexibility with which we approach market demands, our ability to upgrade production lines and processes, and our modularity to allow every possible combination of product specifications and production requirements.

INNOVATION

The willingness to increase our skills and constantly update ourselves, in order to be able to meet market needs and seize new opportunities, are motivations that have always driven us to invest in our production departments, equipping ourselves with the latest generation production plants, automating and digitizing production and monitoring processes.

Our propensity for innovation urges us to continuously search for systems to improve production processes in order to take new paths and provide an answer to our customers even before the question arises.

RESPONSIBILITY

At Car Plast Extrusion, we place particular value on corporate responsibility, expressed in two equally fundamental aspects: social responsibility and environmental responsibility.

Creating work responsibly also means guaranteeing the rights of those who perform it: for this reason, Car Plast Extrusion is constantly committed to ensuring the well-being and health of all staff, guaranteeing not only a safe working environment but also a better quality one.

We consider and evaluate every aspect of the company: from staff training through information and communication of objectives, the introduction of rules and procedures, to prevention of risks related to the job performed, from cleanliness of workplaces, machines and plants, to evaluation and awareness-raising of suppliers on the need to comply with hygiene and safety regulations.

We also pay the utmost attention to environmental protection: from simple separate waste collection, to evaluations on how to reduce and optimize resources, to the search for materials and solutions to reduce the impact of our production, the company's commitment continues to increase.

Aware of the effects that the plastic sector can have on the community, we support, operate, and share every behavior oriented towards sustainability and the search for new opportunities to safeguard natural resources.

PEOPLE

Each figure within Car Plast Extrusion is, first and foremost, a person who brings a fundamental added value: for this reason, the company promotes their training and growth so that they can express their full potential, both professionally and personally.

For Car Plast Extrusion, work is based on meritocracy, equal opportunities, and diversity: only by embracing this vision is it possible to build a united, responsible, and highly professional team. The plastic experts of Car Plast Extrusion are people full of passion, determination, and a willingness to take on challenges, who approach every challenge as an opportunity for improvement and personal and professional growth.