RESPONSIBILITY

Environmental Responsibility

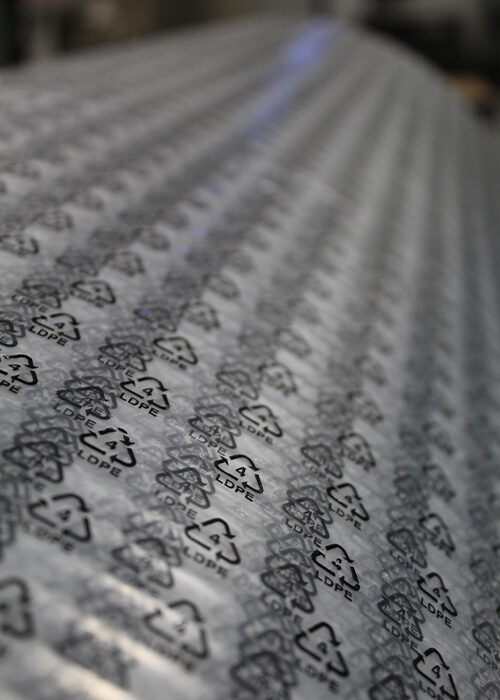

A more conscious use of plastic is not only a market prerogative but also a fundamental moral requirement for achieving circular economies. That’s why Car Plast Extrusion is committed every day to studying more sustainable products by reducing film thickness and researching raw materials from renewable sources.

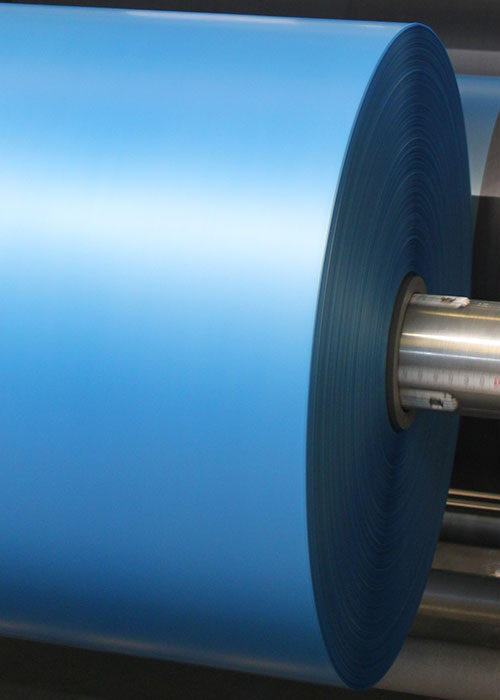

The company’s commitment is also realized through constant monitoring and optimization of its production processes to reduce production waste and reuse it in its plants. Furthermore, Car Plast Extrusion has invested in the introduction of automated systems for raw material retrieval and transportation to reduce granule movement and transportation. The company has also installed a state-of-the-art temperature control system.

Since 2015, the company has been using energy produced by the photovoltaic system installed on its roof, and it manages its waste through targeted recycling. Our commitment to the environment to build a more sustainable development model has led us to undertake the project of obtaining UNI EN ISO 14001:2015 Certification.

The more conscious use of plastic is a moral requirement for achieving a circular economy.

Operating responsibly is our priority because the value we create is only such if it is also for our employees, partners, the environment and society as a whole.

Social Responsibility

Car Plast Extrusion pays close attention to its personnel by providing the necessary tools to ensure the safety of its facilities and the well-being of each employee.

The company aims to build a safety culture where every internal and external figure takes a proactive approach to ensure that health and safety are values to be guaranteed and safeguarded.

Workplace safety is a top priority for us, and to ensure it, we have already launched a program to obtain UNI EN ISO 45001:2018 Certification.

In addition to promoting periodic updates and safety-oriented behaviors within the company, Car Plast Extrusion’s commitment is also oriented towards personal well-being. The mood and motivation of each employee are essential elements to guarantee a quality work environment.

The pursuit of this goal starts with communication: the company supports and protects a dialogue based on respect and cooperation, with the aim of offering a rewarding, meaningful, and safe workplace for all its employees. For Car Plast Extrusion, social responsibility also means recognizing each employee’s time as a precious asset, committing to ensuring a correct balance between private life and work.

Responsibility

Environmental Responsibility

A more conscious use of plastic is not only a market prerogative but also a fundamental moral requirement for achieving circular economies. That’s why Car Plast Extrusion is committed every day to studying more sustainable products by reducing film thickness and researching raw materials from renewable sources.

The company’s commitment is also realized through constant monitoring and optimization of its production processes to reduce production waste and reuse it in its plants. Furthermore, Car Plast Extrusion has invested in the introduction of automated systems for raw material retrieval and transportation to reduce granule movement and transportation. The company has also installed a state-of-the-art temperature control system.

Since 2015, the company has been using energy produced by the photovoltaic system installed on its roof, and it manages its waste through targeted recycling. Our commitment to the environment to build a more sustainable development model has led us to undertake the project of obtaining UNI EN ISO 14001:2015 Certification.

Social reposibility

Car Plast Extrusion pays close attention to its personnel by providing the necessary tools to ensure the safety of its facilities and the well-being of each employee.

The company aims to build a safety culture where every internal and external figure takes a proactive approach to ensure that health and safety are values to be guaranteed and safeguarded.

Workplace safety is a top priority for us, and to ensure it, we have already launched a program to obtain UNI EN ISO 45001:2018 Certification.

In addition to promoting periodic updates and safety-oriented behaviors within the company, Car Plast Extrusion’s commitment is also oriented towards personal well-being. The mood and motivation of each employee are essential elements to guarantee a quality work environment.

The pursuit of this goal starts with communication: the company supports and protects a dialogue based on respect and cooperation, with the aim of offering a rewarding, meaningful, and safe workplace for all its employees. For Car Plast Extrusion, social responsibility also means recognizing each employee’s time as a precious asset, committing to ensuring a correct balance between private life and work.

Da sempre, Car Plast Extrusion ha focalizzato i propri sforzi e investimenti sulla creazione di un know-how che le permettesse di ottimizzare le proprietà dei diversi polimeri, allo scopo di offrire soluzioni che soddisfino al meglio le esigenze di ciascun cliente. Allo stesso tempo, la produzione dell’azienda si presenta come il risultato di un attento operato da parte di un gruppo di lavoro motivato, sempre pronto a svolgere il proprio ruolo con passione e impegno.